With the advent of industry 4.0 era, industrial intelligence has become a new theme of manufacturing industry. China’s traditional industry, relying on the production and development mode of rough and cheap labor force, is facing difficulties and experiencing a profound change.

Taking the casting cleaning and polishing industry in the downstream area of casting industry as an example, most domestic manufacturers still use the traditional manual grinding method. This way of grinding is low in efficiency, unstable in product quality, high in production environment pollution, and the most important health problem of grinding workers is widespread in the industry.

To change this situation, we must first improve the level of automation in the production process, which is also the pursuit of social responsibility entrepreneurs. Recently, an engine manufacturer in China has achieved another major breakthrough in the transformation from made in China to intelligent manufacturing in China.

A well-known Chinese state-owned engine co., ltd. which was founded in the 1950s, is the earliest professional production of heavy-duty high-speed diesel engine large-scale backbone enterprises and national high-tech enterprises. As a large industrial enterprise with strong technical requirements, it has become an inevitable demand to introduce cutting-edge high-tech to seek new development.

In the field of cylinder block grinding of diesel engine, how to achieve automatic grinding without artificialization has always been a difficult problem for this large engine enterprise. It is in this context, which together with Yuyang the automotive engine cylinder automation grinding project was successfully implemented.

Where is the difficulty for the automation of cylinder block?

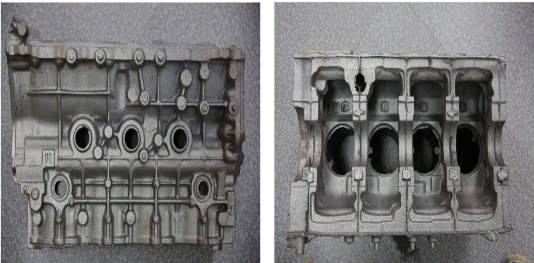

First of all, the casting factors. There is great uncertainty because castings are all blank when they are just produced. For example, casting shrinkage deviation, casting expansion box, pouring temperature of molten iron, dislocation of sand box, incomplete sand core and tamping degree of sand box can all affect the casting deviation of the workpiece, which may lead to the sharp increase of burrs, up and down deviation, flying edge thickening, wrong edge and so on.

These casting deviations greatly affect the positioning accuracy and repeat positioning accuracy in automatic grinding.

Secondly, non-standard component factors. Because of the difference of each artifact deviation, in the process of machining may be cut, or can’t effectively remove the residual amount of riser and flash and other issues, to produce great impact on the quality of grinding cylinder body, and can also can cause a difficult fixture design, and may also affect the trajectory planning of robot, which can lead to the original industry common phase of polishing.

Finally, check the proofreading factors. The physical surface of the casting is rough, so there is often a big deviation in laser measurement and laser detection, even the compensation calculation has a big error, which brings difficulties to the cylinder measurement and accurate positioning.

To sum up, many enterprises have been on the road of technological exploration and have not made a major breakthrough in the automatic grinding of cylinder block.

Independent research and development, Yuyang has breakthrough in the technical difficulties of the industry

After taking over the cylinder automatic grinding project of the state-owned engine co., LTD., Yuyang specially assigned the chief expert who had participated in the national major automation technology project to participate in the research and development, fully considering the technical difficulties in the above industry, and to overcome all kinds of difficulties, and finally overcome the technical problems in the industry.

The engineer in charge of the project said that the project team first improved the deviation of the casting clamps through tests and found effective compensation measures. In this automatic grinding project, the advantages and disadvantages of the measured points in each part are compared and calculated again. When selecting the measuring points, the variation points of the cylinder block, the cutting and grinding path of the cylinder block and the points, lines and surfaces that can affect the machining quality are taken into full consideration.

When clamping the cylinder block, cylinder was selected as the clamping point, and some stable points of the lower cylinder block were selected as the fixing point, which was determined after repeated tests. In this way, both the proportional algorithm and the differential method are easier to achieve the accuracy of detection.

Yuyang specialized more in the development of a system of procedures to control compensation measures. During the implementation, after the cylinder is measured by laser, the corresponding data is transmitted to the control system in real time, and the specially developed software and modules for this project are compared and calculated, so as to generate a compensation program and guide the robot to cut and polish the cylinder.

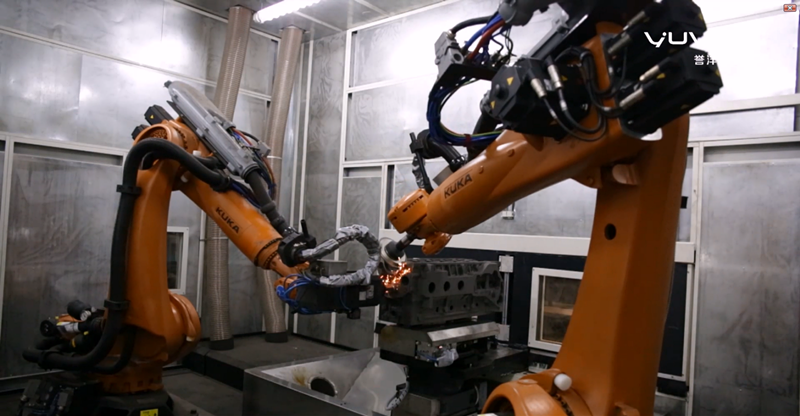

Secondly, the project team re-planned the trajectory of the robot. Yuyang has close cooperation with KUKA, Siemens and other companies. In the research and development and practice, the soft implementation of 3d simulation with executive software solves various possibilities of offline programming. The calculation software developed by Yuyang can repair and compensate the planning path of the robot, so that the simulation effect is close to the real machining track. Then the simulation software of the robot is used for calibration and re-planning, making the trajectory planning more real and more efficient.

Finally, the choice of polishing products is reasonable. People in the industry know that castings vary in size, quality and structure. For different types of castings, Yuyang has successfully developed intelligent grinding equipment and intelligent robot as early as 2015. It can be said that different types of castings can be handled with ease.

In this project practice, how does Yuyang choose to polish the product?

onsidering the complex structure and poor consistency of automobile engine cylinder block casting, the requirements for grinding are more precise and flexible, and the engine is a medium-large casting, which requires a larger working space and is more suitable for grinding by robots. (Picture below)

- GDT210 was selected as the robot in this auto cylinder automatic grinding project, and the engineer provided a list of characteristics of this robot.

- Grinding expert for cylinder block/head

- The maximum workpiece weight is 400 kg.

- It can be equipped with two robots to work at the same time.

- Flexibility — offline programming

- Excellent fixture design

- 30 minutes to complete the replacement of fixtures and tools

- Offline programming does not stop

- Exquisite flexible flexible dye-double station workbench conversion system

- Set workpiece loading and unloading as one

- Reduce loading and unloading time

- Replace the tray = replace the fixture

- Precise positioning zero error — laser measuring system

- Excellent weapon – 12 stations umbrella knife library

- The robot automatically selects grinding wheels and cutting tools

- External replacement of grinding wheel and cutter is simple and convenient

- Wear warning function

- Diamond material

- Efficient and environment-friendly — automatic chip removal system [optional]

- Automatically collects iron filings without manual cleaning.

- Comparable to the top European and American technology, the price is only a second

China’s manufacturing industry as a whole overcapacity, corporate profits and production costs control are all inseparable. Yuyang in the independent research and development of automation technology has made a major breakthrough in the industry at the same time, further for the enterprises to consider the cost problem.

Conclusion

In this project, Yuyang adopts a grinding robot specially designed for engine cylinder block, which completely realizes manual replacement. In terms of core technologies, laser measurement system, dual-station workbench conversion system, knife stock design, fixture design, robot simulation planning and other high-difficulty technology applications and design schemes surpass similar products in Europe and America. Most importantly, the price of Yuyang intelligent grinding products is only half of the same kind of foreign products.

Save money, and operate efficiently, this is all intelligent technology products for the development of the industry to bring the Gospel, Yuyang ‘s intelligent grinding robot is the same. Reputation in the industry of intelligent automobile cylinder grinding and the success of the project delivery, meaning that the robot opened a new chapter in the field of casting cleaning polishing, and independent innovation concept in the field of casting cleaning polishing off at a time.

This well-known state-owned engine co., ltd. will further cooperate with Yuyang to fully realize auto-related castings on the basis of successful implementation of automatic grinding project of cylinder block.