CNC or robot… is this the real question?

Foundries while making the decision to invest in automatic grinding find themselves facing the key question: which is the right technology for my needs?

The crucial choice of what is best for the foundry finishing shop is, most of the times, made more on the perception of the general automation market trends than on a detailed analysis of the foundry’s unique needs.

The robot era: pros and cons of this solution

We live in an era where robots (anthropomorphous, cobots, scara, exaphod and so on) are filling up each and every corner of the industry, coupled with AI SW and vision system devices to replace human labor. Robotic solutions are simply seen as the right choice for all operations when going from manual to automatic.

Indeed, thanks to their extreme flexibility, robots can almost replace workers in all jobs and when used in combination with a vision system and an artificial intelligence they can reach an outstanding level of reliability.

Many times what is not properly considered about the robots is that they also have technical limits, due to their own design, which could result in the worst solution for certain applications.

The real needs of a foundry

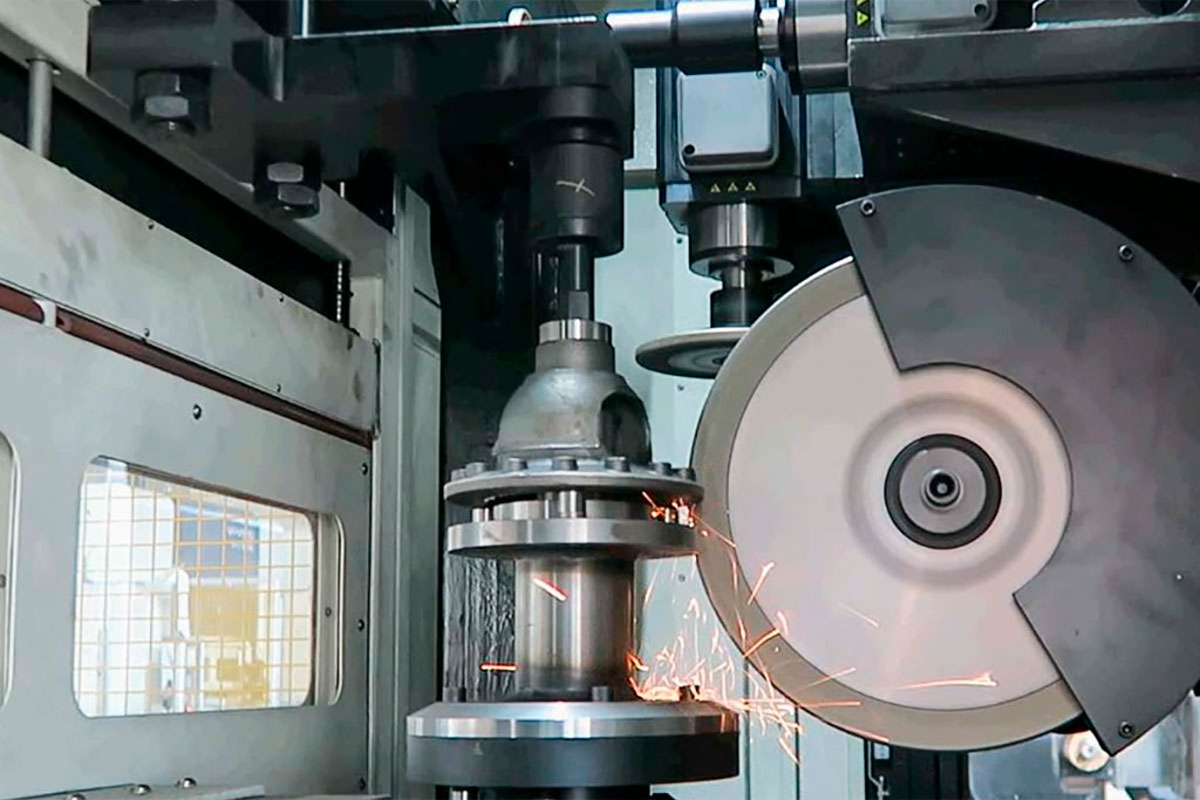

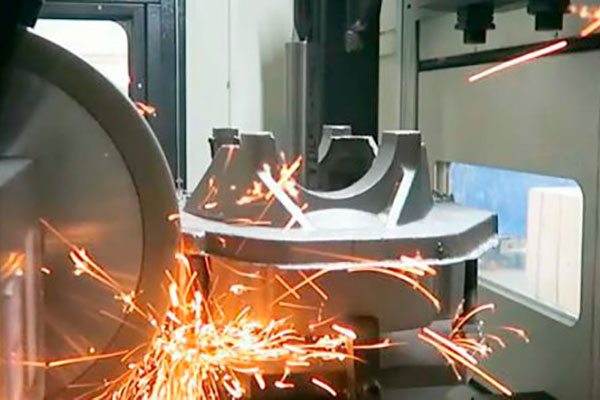

In foundries where heavy operations take place on a daily basis like continuous cutting on hard materials (eg. iron or stainless steel) or in automotive oriented foundries where high production standards and consistent output are requested, a machine-based solution could be by far a better choice than a robotic one.

In foundries where complex castings with multiple cores are made the requirements for a lot of inside finishing may call for a robotic arm equipped with small tools able to reach the more intricate areas.

The feasibility study must be done by experts

At the end of the day each foundry is a unique world and so must be the solution chosen for the finishing shop. A proper decision should be taken only after an accurate feasibility study carried out by experts of the foundry sector, who know the main aspects to consider:

- Product mix

- Volumes

- Foundry business model

- Required operations

- Knowledge and experience in automation

- Staff skills

Relying on general purpose system integrators who have installed hundreds of robotic cells for several applications (handling, assembling, painting etc.) but who are confronting themselves for the first time with the foundry environment could turn out in a major failure.

Calculations on paper and 3D simulations can help a lot to sketch a first estimate but if they are not properly supported by a consistent infield experience the solution that those simulations would prospect will not work well in a finishing shop scenario. The whole operation will result to be inefficient, frustrating for the end users and it will end up being unfortunately much more expensive than anyone could have planned.

Even though foundry is a niche market, the right experts can prove, with real business cases, that throughout the years they have really gained valuable expertise in every automatic grinding solution available (CNC / robotic / SPM). They can really help to evaluate which one is better, more efficient and cost effective in the long run according to the different requirements.

Ultimately the key question is not: “CNC or robot?” but SHOULD be “who are the right people to consult when going from manual to automatic? “

Should they just be specialists in robotic applications, or should they be professionals who are not partial to one specific technology but have enough infield expertise and deep knowledge of all available solutions so that they can really advise what is the best choice for each and any individual case?